The construction of a modular house is made of the best material available on the market – i.e. coniferous wood dried with chambers up to 12-18%, the wood is in the C24 strength class, which is imported from Scandinavia, where it grows in a harsh climate, thanks to which the rings are more dense (the wood is properly sorted, construction timber C24 must withstand rotting with a value of 24MPa, which corresponds to a resistance of 1.56T) The timber has the technical approval EN14801-1: 2005 + A1: 2011 and the CE mark.

Foundation / Foundation

Installation of modular houses is most often carried out on a point foundation:

Foundation columns:

They are made of ready-mixed concrete C16 / 20 to a depth of approx. 70-80 cm into the ground and protrude approx. 10-15 cm above the ground, the poles are additionally reinforced with Ø 12 mm rods, geotextile is spread between the poles, which prevents vegetation from growing. This solution ensures air flow under the modular house, which ensures no mold and fungus development from the bottom, in addition, the MFP board is painted with a dispersite that does not let moisture penetrate into the structure. On such foundations you can safely erect a wooden all-year-round house – even of a large size.

Foundation blocks:

They are made / stabilized on a cement-sand ballast, the height of the arrangement is approx. 10-15 cm above the ground, between the poles there is a geotextile that does not allow vegetation to grow. This solution ensures air flow under the modular house, which ensures no mold and fungus development from the bottom, in addition, the MFP board is painted with a dispersite that does not let moisture penetrate into the structure.

Structural sections

Buildings in the cross-sections described below meet the requirements for buildings for 2021. (building with insulation). From 2021, only energy-efficient houses can be built, for which the value of the building’s demand indicator for non-renewable primary energy (EP) cannot exceed 70 kWh / (m2 * year).

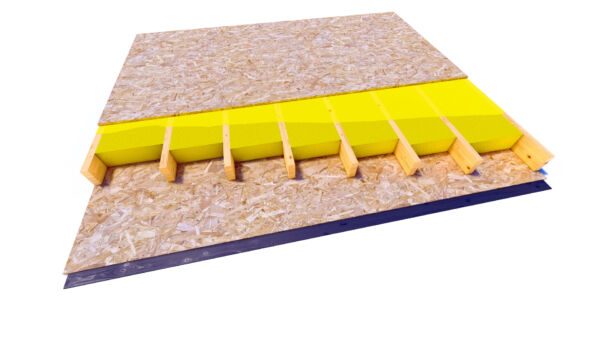

Floor cross-section: λ=0,20 (W/m²K)

- OSB 22mm board

- Vapor barrier foil

- Construction 45x145mm (C24)

- Mineral wool 15cm, λ = 0.033 (W / m²K)

- OSB 10mm board (secured with dispersite)

- Slab 45x145mm (C24) secured with a dispersite

Wall cross-section: λ=0,20 (W/m²K)

- Spruce elevation board gr. 19mm

- Windproofing

- Construction 45 × 145 (C24)

- Mineral wool 15cm, λ = 0.033 (W / m²K) λ=0,033 (W/m²K)

- Vapor barrier

- GKF board (fireproof)

Ceiling-roof cross-section: λ=0,15 (W/m²K)

- Surface heat-sealable roofing felt

- Heat-sealable underlay paper

- 15mm OSB board

- Roof structure 45x145mm (C24)

- Mineral wool 15 + 5cm, λ = 0.033 (W / m²K)

- Vapor barrier

- GKF board (fireproof)